Arcing Fault Hazards

Arcing fault hazards exist at all live electrical panels and precautions must be taken when opening any one of them.

An Arcing Fault is the flow of current through the air between phase conductors or between phase conductors and a neutral or ground, and can be caused by any number of things, ranging from faulty panel wiring to simply dropping a screwdriver or other tool inside a live panel. They can even occur when any conductive object gets too close to a high-amp current source or by simple equipment failure (i.e., opening or closing disconnects). The hazards of arcing faults come in multiple forms.

An Arc Flash is exposure to the tremendous thermal energy released by an arcing fault. Arc Flash can occur if a conductive object gets too close to a high-amp current source or by equipment failure (for instance, opening or closing disconnects). The arc can heat the air to temperatures as high as 35,000° F, so hot that even metal inside the panel can be vaporized. The heat of an arc flash can cause incurable third degree burns and can even ignite clothing from up to ten feet away.

An Arc Blast is exposure to the pressure blast released by an arcing fault. When conductive metals are vaporized by the immense heat of an arcing fault, they expand to 67,000 times their volume instantaneously. This rapid expansion results in an explosion of concussive forces that can propel molten metal and shrapnel away from the arc center.

Electrical maintenance personnel should be fully trained in arc flash safety and protection procedures before attempting any maintenance on electrical equipment.

The above image shows sequential photos of one of many staged tests that helped to understand and quantify the effects of arcing faults on workers. In this test, mannequins with temperature and pressure sensors were placed in the test cell. This was a 480 volt, three-phase system with an available three-phase short-circuit current of 22,600 symmetrical rms amperes. A noncurrent limiting over current protective device was the nearest upstream protective device. An arcing fault was initiated in a combination motor controller enclosure. The arcing fault quickly escalated into a three-phase arcing fault in the enclosure. The current flowed for 6 cycles (1/10 second). The temperature recorders (with maximum temperature limit of 475 °F) on the neck and hand of the mannequin closest to arcing fault were pegged (beyond 457° F limit) (threshold for incurable burn is for skin to reach 205° F for 1/10 second).

The pressure sensor on this mannequin’s chest pegged the recorder at over 2160 lbs/ft2 (the threshold for severe lung damage is 2160 lbs/ft2).

Arc Flash Safe Practices:

- Always observe the safe working depth and clearance for turning on the disconnect switch.

- Never face a disconnect when placing it into the open or closed position; stand off to the side of the panel and turn your body away from the disconnect.

- Always wear PPE (personnel protective equipment) appropriate to the hazard present as dictated by established flash protection boundaries (FPBs).

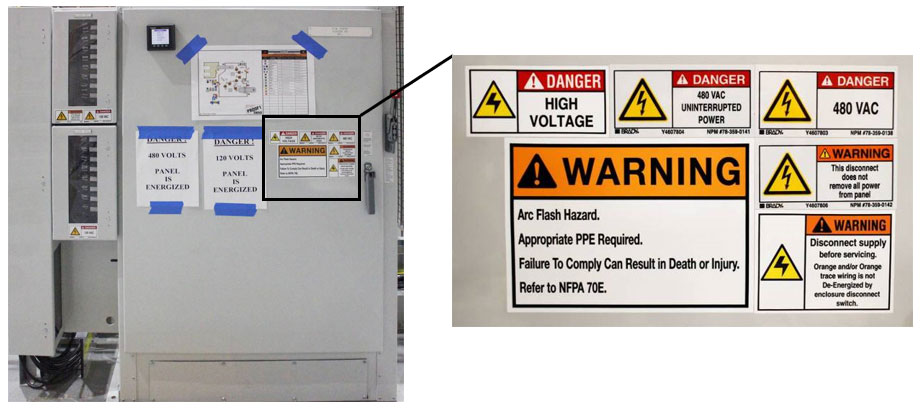

- Be aware of all warning labels and understand them fully before attempting to service.

NFPA 70E

An electrical incident can claim lives and cause permanently disabling injuries. Hundreds of deaths and thousands of burn injuries occur each year due to shock, electrocution, arc flash, and arc blast—and most could be prevented through compliance with NFPA 70E: Standard for Electrical Safety in the Workplace®. Originally developed at OSHA's request, NFPA 70E covers the latest information about the effects of arc flash, arc blast, and direct current (DC) hazards, as well as recent developments in electrical design and Personal Protective Equipment (PPE).

110.16 FLASH PROTECTION. Switchboards, panelboards, industrial control panels, and motor control centers in other than dwelling occupancies that are likely to require examination, adjustment, servicing, or maintenance while energized, shall be field marked to warn qualified persons of potential electric arc flash hazards. The marking shall be located to be clearly visible to qualified persons before examination, adjustment, servicing, or maintenance of the equipment.

FPN No. 1: NFPA 70E-2000, Electrical Safety Requirements for Employee Workplace, aids in determining severity of potential exposure, planning safe work practices, and selecting personal protective equipment.

FPN No. 2: ANSI Z535.4-1998, Product Safety Signs and Labels, provides guidelines for the design of safety signs and labels for application to products.