Equipment Lockout

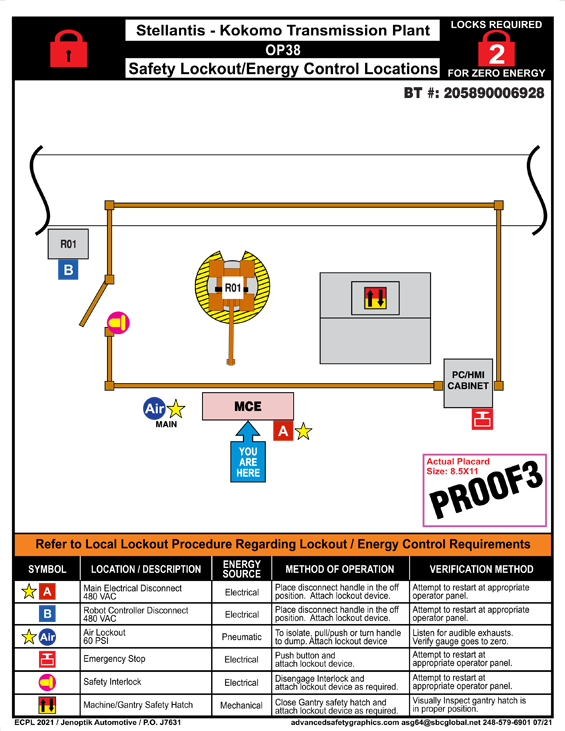

Refer to the LOTO Placard posted on the equipment for energy sources, lockout procedures, and verification procedures.

If the machine or equipment is operating, it shall be shut down using normal shutdown procedures. Refer to the operating section of this manual for shutdown procedures.

When service or maintenance is to be conducted, the equipment must be locked and tagged out following all plant LOTO procedures. Other alternative measures that provide effective employee protection may be used for conducting minor inspections, adjustments, or servicing.

Before shutting down the equipment to lockout energy sources, the employee performing the procedure, or the supervisor shall inform affected employees (such as equipment/process operators) of the intention to shut down the equipment.

Consult the lockout / tagout placard posted on the main electrical power distribution panel (PDP) to assess the task to be performed as it relates to the energy sources that could cause injury if energized or released during the assigned task. The employee should contact his/her immediate supervisor if there are any questions about the identification of potential energy sources.

Consult the graphic placard and procedures placard posted on the main electrical power distribution panel (PDP) to assess the task to be performed as it relates to the energy sources that could cause injury if energized or released during the assigned task. The employee should contact his/her immediate supervisor if there are any questions about the identification of potential energy sources.

If more than one person is to perform work on the equipment, each employee must place his / her personal safety lock on the safety gate and the energy source using a multiple lock device (scissor lock).